Industrial steel structures in Riyadh are crucial for various sectors, including manufacturing, logistics, and energy. At Saudi Steel Work, we ensure these structures meet safety and durability standards in accordance with international guidelines. Our expert services encompass design, engineering, and construction management, leveraging advanced technologies to achieve optimal performance. We prioritize project management to keep timelines and budgets aligned while maintaining the highest quality. Clients experience transparent communication throughout the process, ensuring that projects meet their specific objectives. For more information on our comprehensive approach and the benefits of choosing Saudi Steel Work, please visit our website.

Why Choose Our Services

Choosing the right service provider for industrial steel structures in Riyadh is essential for project success. Clients must prioritize reliability, expertise, and adherence to timelines when selecting a partner. A reputable provider guarantees that all structural requirements are meticulously met, minimizing risks associated with project delays and cost overruns.

Additionally, a focus on quality materials and innovative design leads to enhanced durability and efficiency in the construction process. A capable service provider also offers a transparent communication channel, allowing clients to maintain control over project developments and modifications.

This level of engagement fosters trust and satisfaction, empowering clients to make informed decisions. Ultimately, choosing the right partner directly influences the overall success and sustainability of industrial steel projects in Riyadh.

Our Expertise & What We Offer

Harnessing extensive industry knowledge, the team specializes in delivering high-quality industrial steel structures tailored to the unique needs of clients in Riyadh.

Their expertise encompasses a wide range of services, including design, engineering, and construction management, guaranteeing that every project meets stringent quality standards and specifications.

The team employs advanced technologies and methodologies to optimize structural integrity while adhering to safety regulations.

By fostering collaboration with clients throughout the project lifecycle, they assure alignment with client objectives and timelines.

The firm prioritizes innovative solutions that enhance efficiency and sustainability, enabling clients to maintain control over their investment.

This commitment to excellence positions them as a leader in the industrial steel sector, ready to address the challenges of modern construction demands.

Industries We Serve

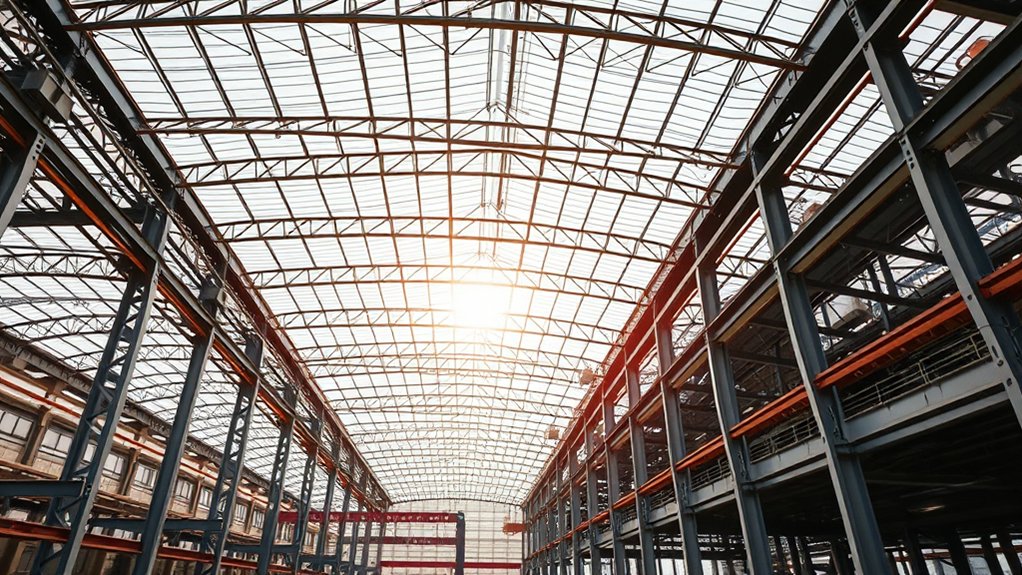

The extensive expertise of Saudi Steel Work in industrial steel structures spans a diverse array of industries in Riyadh. They cater specifically to sectors such as manufacturing, logistics, and energy, ensuring that each project aligns with the unique requirements of these industries.

In the manufacturing sector, Saudi Steel Work delivers robust frameworks that support heavy machinery and production lines. For logistics, their steel structures facilitate efficient warehousing and distribution centers, optimizing operational flow.

In the energy sector, they construct durable facilities that are designed to withstand demanding environments. Additionally, their adaptability allows Saudi Steel Work to serve emerging industries, keeping them at the forefront of innovation.

Benefits of Professional Services

While businesses may consider various options for constructing industrial steel structures, the benefits of professional services stand out remarkably. Engaging experienced professionals guarantees adherence to industry standards, resulting in enhanced safety and durability of the structures.

Their expertise allows for precise planning and execution, minimizing costly delays and rework. Additionally, professionals provide access to advanced technologies and innovative solutions, optimizing both design and functionality. This not only streamlines the construction process but also enhances long-term operational efficiency.

Moreover, professional services often include thorough project management, guaranteeing that timelines and budgets are meticulously adhered to. In an environment where control over resources and outcomes is paramount, leveraging professional services can greatly elevate the quality and reliability of industrial steel structures.

How Our Process Works

Understanding the intricacies of constructing industrial steel structures at Saudi Steel Work begins with a well-defined process. The initial phase involves thorough planning, where project specifications and client requirements are meticulously gathered.

Following this, advanced design techniques are employed, utilizing sophisticated software to create precise structural models tailored specifically for each project. Once the designs are approved, procurement of high-quality materials is initiated, ensuring durability and strength.

Subsequently, skilled teams at Saudi Steel Work execute the fabrication of steel components in controlled environments, adhering to predetermined timelines.

The final stage involves precise assembly on-site, where logistics and safety protocols are strictly enforced. Each step of this process is designed to maintain control over quality, ensuring that the final structure meets the highest standards of safety and functionality, all customized to the client's specifications.

Quality & Standards

Quality and standards are of utmost importance in the construction of industrial steel structures at Saudi Steel Work. Adhering to international standards, such as ISO 9001 and ASTM specifications, ensures that our materials and processes meet stringent performance criteria.

This commitment is reflected in our selection of high-grade steel, which enhances durability and safety. Regular inspections and testing are integral to our construction process, allowing us to identify and mitigate potential issues before they escalate.

Additionally, employing certified professionals guarantees that all work aligns with established guidelines, thereby reducing risk and ensuring structural integrity.

Frequently Asked Questions

What Materials Are Commonly Used in Industrial Steel Structures?

The materials commonly utilized in industrial steel structures typically include carbon steel, stainless steel, and alloy steel due to their strength, durability, and resistance to various environmental factors, ensuring structural integrity and longevity in construction projects.

How Long Does It Take to Complete a Steel Structure Project?

The duration for completing a steel structure project typically ranges from several months to over a year, depending on project complexity, design specifications, and site conditions. Effective planning and resource management can greatly influence timelines.

Are There Any Specific Regulations for Steel Structures in Riyadh?

Specific regulations for steel structures exist, emphasizing safety, quality, and environmental considerations. Compliance with local codes and standards guarantees structural integrity, promotes sustainability, and mitigates risks, providing stakeholders with confidence in their construction projects.

What Is the Typical Lifespan of an Industrial Steel Structure?

The typical lifespan of an industrial steel structure ranges from 30 to 50 years, depending on various factors including maintenance, environmental conditions, and design quality, enabling owners to plan for future investments and replacements effectively.

Can Steel Structures Be Modified After Construction?

Steel structures can indeed be modified post-construction, allowing for enhancements or repurposing. This adaptability is beneficial for organizations seeking to optimize functionality, guarantee compliance with evolving regulations, or accommodate changing operational needs effectively and efficiently.