Why Choose Our Services

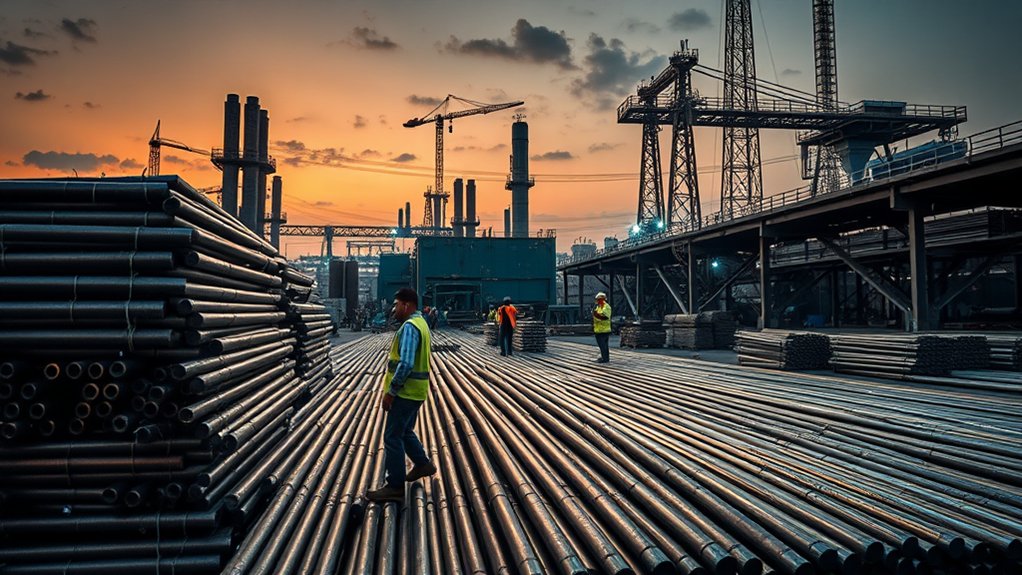

When considering steel product manufacturing in Makkah, clients often seek reliable partners who can deliver high-quality materials and exceptional service.

The competitive landscape necessitates a focus on precision, consistency, and adherence to industry standards. Clients require partners who understand the intricacies of their projects, ensuring that the materials supplied meet specific requirements and timelines.

Additionally, transparency in communication and a commitment to efficiency are paramount, as clients prefer to maintain control over their supply chain. By choosing a service that prioritizes these elements, clients can confidently manage their projects, knowing they have the backing of a steadfast partner.

Ultimately, the right choice in steel product manufacturing is essential for achieving both immediate goals and long-term success.

Our Expertise & What We Offer

Delivering excellence in steel product manufacturing, the company leverages extensive industry experience and technical expertise to meet diverse client needs in Makkah.

Its commitment to quality is evident in the rigorous standards upheld throughout the production process. The team utilizes advanced technology and innovative techniques to guarantee precision in every product, from structural steel to specialized components.

Clients benefit from tailored solutions designed to optimize project efficiency and performance. By maintaining flexibility and responsiveness, the company empowers clients to make informed decisions that align with their specific project requirements.

The expert team is dedicated to providing ongoing support, assuring that clients have the control they need at every stage of the manufacturing process, thereby reinforcing trust and satisfaction in the partnership.

Industries We Serve

Recognizing the diverse needs of various sectors, Saudi Steel Work serves a wide array of industries in Makkah, including construction, automotive, and manufacturing.

By focusing on the specific requirements of each sector, Saudi Steel Work guarantees that its steel products meet the highest standards of quality and durability.

In the construction industry, the demand for robust materials is met with precision-engineered products that facilitate safe and efficient building practices.

In the automotive sector, Saudi Steel Work provides components that enhance vehicle performance and safety.

Additionally, manufacturing industries benefit from tailored solutions that improve productivity and streamline operations.

This targeted approach allows Saudi Steel Work to maintain a competitive edge while effectively addressing the unique challenges faced by each industry.

Benefits of Professional Services

Choosing professional services in steel product manufacturing offers significant advantages that enhance operational efficiency and product quality. Engaging experts in the field guarantees access to advanced technology, streamlined processes, and industry best practices.

This expertise enables manufacturers to maintain rigorous quality standards, minimizing defects and rework. Additionally, professional services often provide tailored solutions, allowing companies to respond effectively to specific market demands and customer requirements.

By leveraging professional knowledge, businesses can optimize resource allocation, reduce waste, and ultimately improve profitability. Moreover, these services facilitate compliance with regulatory standards, mitigating risks associated with legal and safety issues.

In a competitive market, utilizing professional services becomes a strategic advantage, empowering manufacturers to achieve higher levels of control and success.

How Our Process Works

The steel product manufacturing process at Saudi Steel Work in Makkah is meticulously designed to guarantee efficiency and quality at every stage. Initially, high-grade raw materials are sourced, ensuring peak strength and durability. These materials undergo rigorous quality checks before entering the production line.

Advanced machinery shapes and molds the steel, utilizing precise specifications to meet client requirements. Subsequent heat treatment processes enhance the material properties, ensuring resilience against environmental factors. Each phase is monitored with stringent quality control measures, allowing for immediate adjustments if necessary.

Finally, the finished products are subjected to thorough inspections, ensuring they meet industry standards. This systematic approach empowers stakeholders with confidence, ensuring that every product delivered aligns with their specifications and expectations.

Find the Best Steel Company Near You

Neighborhood We Serve

| Name | Zip Code |

|---|---|

| Riyadh | 11564 |

| Jeddah | 21577 |

| Dammam | 31461 |

| Khobar | 31952 |

| Mecca | 21955 |

| Medina | 42311 |

| Tabuk | 71411 |

| Abha | 62521 |

| Khamis Mushait | 62413 |

| Al Khobar | 31952 |

How can one identify the best steel company nearby? First, it is essential to conduct thorough research on local options. Analyzing customer reviews, testimonials, and ratings provides insight into the company's reputation. Additionally, one should evaluate the range of products and services offered, ensuring they align with specific project requirements.

Furthermore, evaluating the company's experience and industry expertise can indicate reliability and capability. Requesting quotes from multiple companies allows for a comparison of pricing and value.

Networking with industry professionals or visiting trade shows can yield recommendations for reputable companies. Ultimately, making informed decisions based on extensive information empowers individuals to select the most suitable steel company for their needs.

Quality & Standards

Ensuring high quality and adherence to industry standards is paramount in steel product manufacturing at Saudi Steel Work. In Makkah, Saudi Steel Work implements rigorous quality control processes to guarantee that all products meet national and international standards.

This commitment to excellence involves using advanced technology and materials, coupled with regular inspections and testing protocols.

Moreover, certifications from recognized bodies serve as proof of Saudi Steel Work's dedication to quality. By adhering to ISO and ASTM standards, the company demonstrates its capability to produce reliable and durable steel products.

In this competitive landscape, a focus on quality not only fosters customer trust but also positions Saudi Steel Work for long-term success.

Ultimately, maintaining stringent quality standards is essential for operational efficiency and market reputation in the steel industry.

Frequently Asked Questions

What Types of Steel Products Are Manufactured in Makkah?

The current question explores various steel products produced in specific regions. Typically, manufacturers might focus on structural steel, reinforcing bars, and specialized components, catering to construction, infrastructure, and industrial needs in diverse markets.

Are Custom Steel Solutions Available for Unique Projects?

Custom steel solutions are indeed available for unique projects, allowing clients to specify dimensions, materials, and designs. This tailored approach guarantees that specific requirements are met, providing flexibility and control over the final product's outcome.

How Can I Request a Quote for Steel Products?

To request a quote for steel products, individuals should contact suppliers directly via their websites or customer service. Providing detailed project specifications and required quantities will facilitate accurate and timely estimates tailored to specific needs.

What Is the Typical Lead Time for Steel Product Delivery?

Typical lead times for steel product delivery vary based on factors such as order size, manufacturing processes, and supplier capabilities. Generally, customers can expect a timeline ranging from a few days to several weeks.

Do You Offer Installation Services for Steel Products?

The company does not provide installation services for steel products. Clients are encouraged to consult with professional installers or contractors to guarantee proper handling and installation, thereby maintaining control over the quality and safety of the final product.