Why Choose Our Services

When considering industrial steel fabrication in Makkah, the advantages of choosing their services become immediately apparent.

Clients benefit from a streamlined process that prioritizes efficiency and precision, guaranteeing projects are completed on time and within budget. The use of advanced technology and quality materials assures durability and strength, providing a competitive edge in construction and manufacturing.

Moreover, the expertise of skilled professionals allows for customized solutions that meet specific client needs, enhancing overall satisfaction. Additionally, their commitment to safety standards guarantees a secure working environment, minimizing risks.

Our Expertise & What We Offer

Clients benefit not only from streamlined processes and skilled professionals but also from an extensive range of expertise in industrial steel fabrication offered in Makkah.

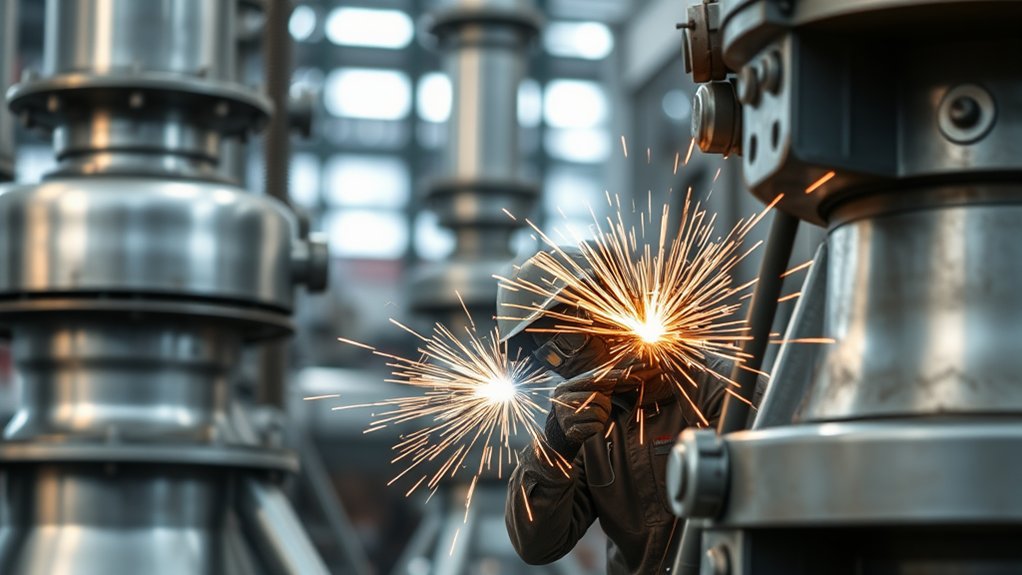

The firm specializes in precision cutting, welding, and assembly techniques that meet stringent quality standards. Equipped with state-of-the-art machinery, the team delivers customized solutions tailored to specific project requirements.

Emphasis is placed on material selection and structural integrity, ensuring durability and safety in every product. Clients can expect thorough support throughout the fabrication process, from initial design consultation to final installation.

This commitment to excellence positions the firm as a reliable partner in achieving desired outcomes efficiently and effectively, giving clients the control they seek over their projects.

Industries We Serve

Serving a diverse array of industries, Saudi Steel Work is a key player in the industrial steel fabrication sector in Makkah. This establishment provides tailored solutions across various fields, including construction, manufacturing, oil and gas, and transportation.

By focusing on the unique requirements of each industry, Saudi Steel Work guarantees that its steel fabrication services meet stringent standards of quality and durability. Their expertise extends to creating customized steel structures, components, and systems that enhance operational efficiency.

Furthermore, they maintain a commitment to innovation, adapting their processes to meet evolving industry demands. Clients from different sectors rely on Saudi Steel Work for its reliability, precision, and ability to deliver projects on time, reinforcing its position as a trusted partner in industrial steel fabrication.

Benefits of Professional Services

Professional services in industrial steel fabrication offer numerous advantages that considerably impact project outcomes. Engaging experts guarantees adherence to industry standards, enhancing product quality and reducing the risk of costly errors.

Professionals bring advanced technology and specialized knowledge, enabling efficient project management and timely delivery, thereby maximizing productivity. Their experience facilitates ideal material selection and innovative design solutions, which ultimately lead to cost savings.

Furthermore, professional services provide thorough support, from initial consultation to final installation, guaranteeing that every aspect of the project aligns with client specifications. By leveraging these benefits, businesses can maintain greater control over their projects, resulting in enhanced operational efficiency and increased competitiveness in a demanding market.

How Our Process Works

The process of industrial steel fabrication at Saudi Steel Work in Makkah begins with a thorough consultation to understand the specific needs and objectives of each project.

Following this, detailed designs are created using advanced software to ensure precision and accuracy. Once approved, high-quality materials are sourced, emphasizing durability and compliance with industry standards.

The fabrication stage involves cutting, shaping, and assembling steel components using state-of-the-art machinery operated by skilled professionals. Quality control checks are implemented at every phase to maintain high standards.

After fabrication, the components undergo finishing processes to enhance aesthetics and provide protection against environmental factors.

Finally, timely delivery and installation are coordinated, ensuring clients retain control over their project timelines and effectively meet their operational demands.

Find the Best Steel Company Near You

Finding the right steel company can greatly impact the success of any construction or fabrication project. Individuals seeking quality steel solutions should prioritize local companies that offer a solid reputation and proven track records. Analyzing potential suppliers involves researching their project portfolios, evaluating customer reviews, and analyzing pricing structures. It is crucial to take into account the range of services offered, including customization options and delivery capabilities. Engaging with representatives can provide insight into their responsiveness and expertise. Prospective clients should also inquire about certifications and industry affiliations, which can indicate reliability and professionalism. By thoroughly vetting options, one can make an informed decision and select a steel company that aligns with project requirements and expectations, ensuring a smoother execution phase.

Neighborhoods We Serve:

| Name | Zip Code |

|---|---|

| Riyadh | 11564 |

| Jeddah | 21577 |

| Dammam | 31461 |

| Khobar | 31952 |

| Mecca | 21955 |

| Medina | 42311 |

| Tabuk | 71411 |

| Abha | 62521 |

| Khamis Mushait | 62413 |

| Al Khobar | 31952 |

Quality & Standards

Quality and standards are paramount in the industrial steel fabrication sector, especially in Makkah. At Saudi Steel Work, adherence to stringent international and local standards ensures that our fabricated steel products meet the highest specifications for safety and durability.

We implement rigorous quality control measures throughout the manufacturing process, from material selection to final inspections. Our commitment to certifications such as ISO and adherence to ASTM standards instills confidence in our clients regarding the reliability and performance of their projects.

Furthermore, we prioritize continuous training and development of our skilled personnel to maintain high-quality benchmarks. In a rapidly evolving industry, our dedication to quality and established standards not only enhances operational efficiency but also fosters trust among all stakeholders involved.

Frequently Asked Questions

What Types of Steel Are Commonly Used in Fabrication?

In industrial steel fabrication, various types of steel are utilized, including carbon steel, alloy steel, stainless steel, and tool steel. Each type offers distinct properties, catering to specific structural and functional requirements in diverse applications.

How Long Does the Fabrication Process Typically Take?

The fabrication process duration varies considerably based on project complexity, material types, and available resources. Typically, it spans from a few days to several weeks, ensuring precision and quality in the final product.

Are There Any Eco-Friendly Practices Employed in Steel Fabrication?

Eco-friendly practices in steel fabrication include recycling scrap metal, utilizing energy-efficient machinery, and adopting sustainable sourcing methods. These efforts aim to minimize environmental impact while enhancing operational efficiency and aligning with modern sustainability goals in the industry.

What Is the Typical Cost Range for Steel Fabrication Projects?

The typical cost range for steel fabrication projects varies considerably based on complexity, materials, and labor. Generally, projects can cost anywhere from a few thousand to several hundred thousand dollars, depending on the specific requirements and scale.

Can Custom Designs Be Accommodated in Steel Fabrication?

Custom designs can indeed be accommodated in steel fabrication. This flexibility allows clients to tailor projects to their specific requirements, ensuring that each design reflects individual preferences and functional needs while maintaining structural integrity.