Why Choose Our Services

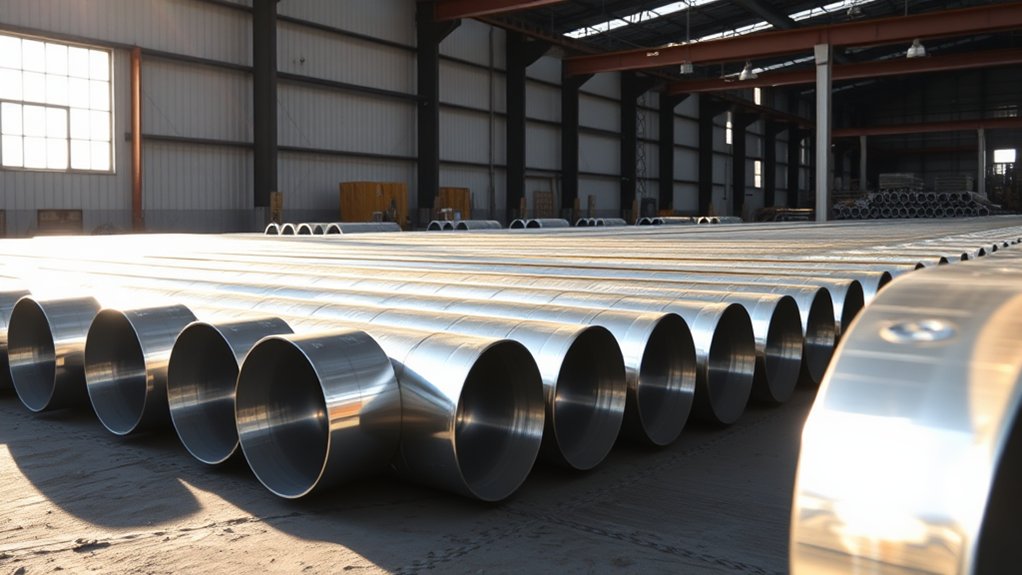

When seeking reliable steel tube solutions, one company stands out for its commitment to quality and customer satisfaction.

This organization prioritizes precision in manufacturing processes, ensuring that each steel tube meets stringent industry standards. Their focus on durability and performance translates into products that thrive in various applications, providing clients with confidence in their choices.

Furthermore, the company embraces transparency in pricing and processes, empowering customers with the knowledge needed to make informed decisions.

With a dedicated team ready to address specific requirements, clients can expect tailored solutions that align with their operational goals.

Our Expertise & What We Offer

While many companies claim expertise in steel tube manufacturing, this organization distinguishes itself through a thorough understanding of industry requirements and advancements.

Their team comprises seasoned professionals who leverage cutting-edge technology to guarantee the highest quality standards. The organization offers a wide-ranging array of steel tube solutions tailored to meet diverse client specifications, emphasizing precision and durability.

They provide a meticulous approach to production, guaranteeing that every tube adheres to rigorous quality control measures. Clients benefit from customized options, allowing for specific dimensions and finishes that suit their unique applications.

Additionally, the organization prioritizes timely delivery and responsive customer service, reinforcing their commitment to customer satisfaction. Through these offerings, they empower clients to achieve operational excellence in their respective sectors.

Industries We Serve

The organization serves a diverse range of industries within the steel sector in Saudi Arabia, recognizing that each sector has unique demands for steel tube solutions.

Key sectors include construction, automotive, oil and gas, and manufacturing. In the construction industry, robust steel tubes are essential for structural integrity and safety.

The automotive sector relies on precision-engineered tubes for performance and durability. For oil and gas, the organization provides corrosion-resistant options suited for harsh environments.

Additionally, manufacturing industries benefit from customized tube solutions to optimize production processes.

By understanding the specific requirements of each industry, the organization guarantees that clients receive tailored products that enhance operational efficiency and meet regulatory standards.

This commitment to industry-specific needs reinforces the organization's position as a leader in steel tube solutions in Saudi Arabia.

Benefits of Professional Services

Recognizing the complexities of the steel industry, professional services offer invaluable expertise that enhances operational efficiency and product quality.

These services provide strategic insights that enable companies to streamline processes, minimize waste, and optimize resource allocation. By leveraging specialized knowledge, firms can implement best practices that guarantee compliance with industry standards and regulations.

Additionally, professional services facilitate risk management, allowing businesses to identify and mitigate potential challenges before they escalate. This proactive approach not only safeguards investments but also fosters innovation within the organization.

Ultimately, engaging professional services empowers companies to maintain a competitive edge in the market, assuring they can respond effectively to evolving demands while maximizing profitability and sustainability.

How Our Process Works

Understanding the intricacies of steel tube production at Saudi Steel Works, the process begins with a thorough assessment of client needs and project specifications. This guarantees that all requirements are clearly defined and understood.

Next, raw materials are meticulously selected, focusing on quality and durability to meet exacting standards. Once materials are procured, advanced manufacturing techniques are employed to shape and weld the tubes, maintaining precision throughout.

Rigorous quality control measures follow, with each tube undergoing testing to confirm compliance with industry regulations. Finally, the tubes are prepared for delivery, assuring they meet the agreed-upon timelines.

Through this structured approach, clients at Saudi Steel Works retain control over their project's outcome, ensuring that the final products align perfectly with their specifications and expectations.

Find the Best Steel Company Near You

Neighbourhoods We Serve

| Name | Zip Code |

|---|---|

| Riyadh | 11564 |

| Jeddah | 21577 |

| Dammam | 31461 |

| Khobar | 31952 |

| Mecca | 21955 |

| Medina | 42311 |

| Tabuk | 71411 |

| Abha | 62521 |

| Khamis Mushait | 62413 |

| Al Khobar | 31952 |

When searching for the best steel company nearby, it is essential to take into account factors such as reputation, product quality, and customer service. Prospective clients should evaluate local firms by reviewing online ratings, testimonials, and case studies to gauge their industry standing. It is advisable to request samples and detailed specifications of products to guarantee they meet the necessary requirements. Additionally, communication with the company's representatives can provide insights into their responsiveness and willingness to address concerns. By prioritizing these elements, customers can confidently select a steel supplier that aligns with their project needs. Ultimately, thorough research empowers clients to make informed decisions, ensuring they obtain quality steel products and reliable service in their vicinity.

Quality & Standards

Quality and standards are paramount in the steel industry in Saudi Arabia, particularly for https://saudisteelwork.com/, as they directly impact the durability and performance of products.

Adherence to international quality benchmarks is critical for manufacturers aiming to establish credibility and reliability. Steel tubes produced by Saudi Steel Work must undergo rigorous testing to ensure they meet specifications for strength, corrosion resistance, and dimensional accuracy.

Compliance with standards such as ASTM and ISO not only enhances product integrity but also assures clients of consistent performance in various applications. Additionally, regular audits and certifications help maintain these standards, enabling Saudi Steel Work to demonstrate its commitment to excellence.

Buyers should prioritize suppliers like Saudi Steel Work, which emphasize robust quality control measures, ensuring the longevity and safety of the steel products they invest in.

Frequently Asked Questions

What Types of Steel Tubes Are Available in Jazan?

Various types of steel tubes exist, including seamless, welded, and structural options. Each type serves distinct applications, meeting specific strength and durability requirements, thereby offering users the flexibility needed for diverse construction and industrial projects.

How Are Steel Tubes Manufactured in Jazan?

Steel tubes are manufactured through processes such as extrusion, welding, and seamless production. These methods involve heating, molding, and cooling raw materials, ensuring precision and structural integrity to meet specific industrial standards and applications effectively.

What Are the Typical Sizes of Steel Tubes Offered?

Typical sizes of steel tubes vary considerably, encompassing diameters from a few millimeters to several inches. Lengths often range from standard lengths up to custom specifications, catering to diverse industrial applications and client requirements.

Can Steel Tubes Be Customized for Specific Projects?

Steel tubes can indeed be customized to meet specific project requirements. Options include varying dimensions, material grades, and finishes, allowing for tailored solutions that enhance performance and compatibility with diverse applications in various industries.

What Is the Average Lead Time for Steel Tube Orders?

The average lead time for steel tube orders typically ranges from two to six weeks, depending on factors such as order size, material specifications, and manufacturing processes, allowing for efficient project planning and execution.