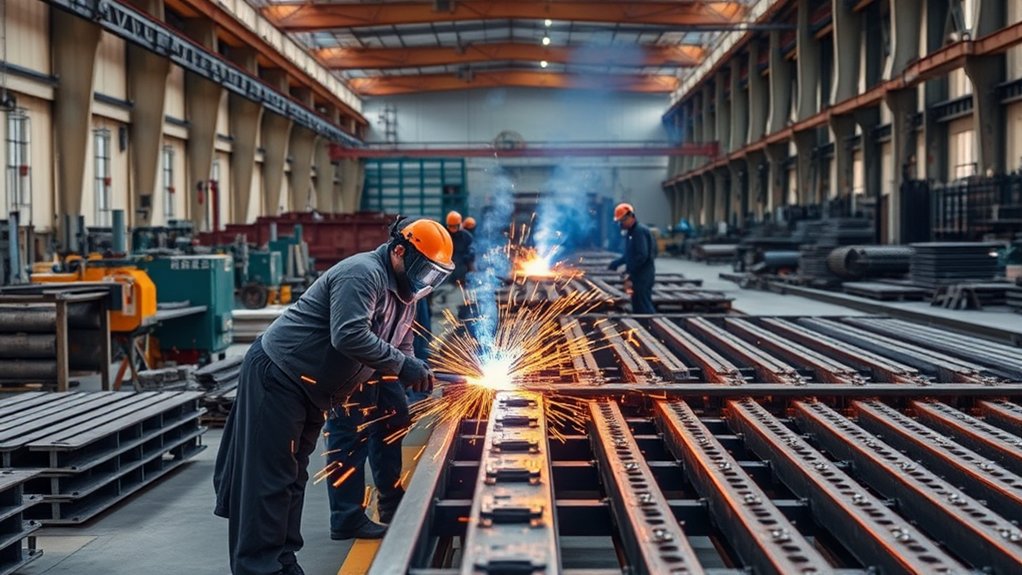

Industrial steel fabrication in Al-Khobar, provided by Saudi Steel Work, offers reliable solutions across various sectors, including construction and oil and gas. Their services prioritize high-quality materials and precision engineering, ensuring projects meet stringent standards. Utilizing advanced technology and skilled professionals, Saudi Steel Work delivers customization and efficiency, enhancing project outcomes. With a strong focus on safety and compliance, these services streamline timelines and reduce costs. For more insights into their capabilities and benefits, further details are available on their extensive offerings at https://saudisteelwork.com/.

Why Choose Our Services

Choosing the right industrial steel fabrication service can greatly impact project outcomes. Selecting a provider with a track record of reliability and precision is critical for maintaining timelines and budgets.

A well-established service guarantees that materials meet stringent quality standards, reducing the risk of defects and rework. Furthermore, a capable fabricator offers advanced technology and skilled personnel, enabling greater customization to meet specific project requirements.

Clients benefit from clear communication and transparency throughout the process, allowing them to maintain oversight and make informed decisions.

Ultimately, choosing the right service empowers clients to achieve their project goals efficiently and effectively, guaranteeing that every aspect of steel fabrication aligns with their strategic vision.

Our Expertise & What We Offer

With years of experience in the industrial steel fabrication industry, the team possesses a wealth of expertise and resources to deliver high-quality solutions tailored to client needs. Their proficiency spans advanced fabrication techniques, ensuring precision and durability in every project.

The team is equipped with state-of-the-art technology, enabling efficient production workflows that meet stringent deadlines without compromising quality. Clients can expect extensive services, from initial design consultation to final installation, ensuring seamless project management.

Additionally, the team emphasizes safety and compliance with industry standards, providing peace of mind throughout the fabrication process. By prioritizing customer satisfaction, they empower clients to maintain control over project specifications, timelines, and budgets, resulting in customized solutions that align with specific operational goals.

Industries We Serve

The expertise in industrial steel fabrication at https://saudisteelwork.com/ spans a diverse range of industries within Saudi Arabia.

Key sectors benefiting from these services include construction, oil and gas, manufacturing, and infrastructure development. Each industry demands unique specifications and standards, requiring precise craftsmanship and adherence to safety regulations.

In the construction sector, fabricated steel components are essential for structural integrity, while the oil and gas industry relies on robust materials to withstand harsh environments.

Manufacturing processes also depend on steel fabrication for machinery and equipment. Additionally, infrastructure projects utilize steel for bridges, roads, and public facilities, ensuring durability and longevity.

Benefits of Professional Services

Numerous advantages arise from engaging professional steel fabrication services.

First and foremost, these experts guarantee high-quality results through precision engineering and state-of-the-art technology. Clients benefit from adherence to industry standards, which mitigates risks associated with structural integrity.

Additionally, professional services streamline project timelines, enabling businesses to meet critical deadlines and maintain operational efficiency. Cost-effectiveness is another significant factor; experienced fabricators optimize material usage and minimize waste, ultimately reducing expenses.

Moreover, professional fabricators offer valuable insights into design and functionality, aiding clients in achieving their specific goals. This level of expertise fosters confidence, allowing businesses to focus on their core operations while entrusting fabrication tasks to skilled professionals.

How Our Process Works

A seamless steel fabrication process is essential to ensuring quality and efficiency in every project at Saudi Steel Work. The procedure begins with a thorough assessment of project specifications, allowing for a tailored approach that meets client requirements.

Next, advanced computer-aided design (CAD) software is employed to create precise blueprints, ensuring accuracy during fabrication. Materials are then sourced from trusted suppliers to guarantee consistency and reliability.

Skilled technicians at Saudi Steel Work utilize state-of-the-art machinery to cut, shape, and assemble steel components with meticulous attention to detail. Throughout the process, rigorous inspections are conducted to identify any discrepancies early, preventing costly delays.

Finally, the finished products are prepared for delivery, ensuring that clients receive their steel components on time and ready for immediate implementation.

Quality & Standards

At Saudi Steel Work, ensuring high quality and adherence to industry standards is paramount, as these factors directly influence project success and client satisfaction.

The company rigorously implements quality control measures throughout its fabrication processes, employing advanced technology and skilled personnel to achieve optimal outcomes. Compliance with international standards such as ISO 9001 guarantees that every project meets stringent quality benchmarks, ensuring durability and reliability in the final products.

Regular audits and inspections further reinforce this commitment to excellence, allowing for timely identification and rectification of any potential issues.

Frequently Asked Questions

What Materials Are Commonly Used in Steel Fabrication?

In steel fabrication, commonly used materials include various grades of steel, such as carbon steel, stainless steel, and alloy steel. Additionally, tools, welding rods, and coatings play essential roles in enhancing durability and performance.

How Long Does a Typical Fabrication Project Take?

The duration of a typical fabrication project varies considerably, often ranging from several weeks to months. Factors influencing timelines include project complexity, material availability, and client specifications, all of which require careful management for timely completion.

Can You Handle Custom Design Requests?

Custom design requests can be accommodated, allowing clients to express their unique specifications. This flexibility guarantees that each project aligns closely with individual needs, promoting a sense of control and satisfaction throughout the fabrication process.

What Is the Typical Cost Range for Fabrication Services?

The typical cost range for fabrication services varies considerably based on project complexity, materials used, and labor involved. Clients should expect to budget accordingly, ensuring they account for all aspects of the fabrication process.

Do You Offer Delivery Services for Finished Products?

The company provides delivery services for finished products, ensuring efficient transportation to clients. This option allows customers to maintain greater control over their projects, facilitating timely completion and minimizing logistical challenges in the process.