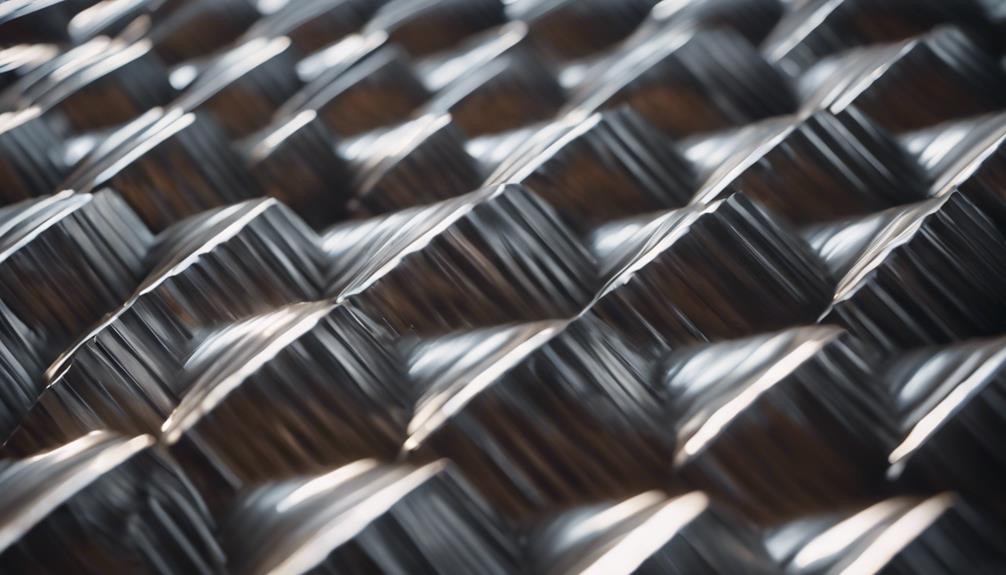

Corrugated steel sheets, coated with zinc for enhanced durability and corrosion resistance, are highly sought-after for roofing and industrial projects. They offer a modern aesthetic and robust protection against the elements, making them a popular choice for their strength and reliability in diverse applications. Consider the various sizes, finishes, and applications of corrugated steel sheets to best suit your project needs.

Key Takeaways

- Galvanized and Galvalume finishes offer enhanced durability and weather resistance.

- Versatile for roofing, siding, paneling, and industrial projects.

- Available in various sizes and gauges to suit different applications.

- Lightweight with high strength-to-weight ratio for structural support.

- Low maintenance and cost-effective long-term solution for construction needs.

Types of Corrugated Steel Sheets

Corrugated steel sheets are classified into various types based on their unique profiles and materials, catering to diverse structural and design requirements in construction projects. One common type is galvanized corrugated steel sheets, which are coated with a layer of zinc to enhance corrosion resistance. These galvanized sheets are popular for roofing due to their durability and cost-effectiveness. Additionally, corrugated steel panels made from galvanized steel offer a sleek, modern aesthetic while providing robust protection against the elements. The versatility of galvanized corrugated steel makes it a preferred choice for a wide range of applications, including roofing, paneling, and industrial projects where strength and reliability are paramount.

Benefits of Corrugated Steel Sheet

With a proven track record of durability and weather resistance, corrugated steel sheets offer a multitude of benefits for various outdoor construction applications. Corrugated galvanized steel is known for its weather-resistant properties, making it a reliable choice for harsh environmental conditions. The high strength-to-weight ratio of these sheets provides excellent structural support without adding excessive weight. Additionally, being lightweight, corrugated steel sheets are easy to handle and install, reducing labor costs. Their low maintenance requirements make them a cost-effective long-term solution. Moreover, the versatility of corrugated steel sheets allows for a wide range of applications such as roofing, siding, and fencing, making them a popular choice in the construction industry.

Corrugated Steel Sheet Sizes

In construction and industrial settings, the sizing options available for corrugated steel sheets cater to a diverse range of project requirements and applications. Standard corrugated metal panels typically range from 26 to 29 gauge, offering durability for various uses in metal roofing and industrial projects. These panels are commonly available in widths of 26 feet, with lengths varying from 8 to 12 feet to accommodate different project sizes. Corrugated steel sheets are often produced in materials like galvanized steel, stainless steel, and aluminum, ensuring quality corrugated options for different applications. Companies like Industrial Metal Supply play a vital role in the supply chain of quality corrugated metal panels, including options like perforated aluminum, to meet the varied needs of construction and industrial projects.

Corrugated Steel Sheet Finishes

When considering options for corrugated steel sheets, the selection of appropriate finishes such as Galvalume and Galvanized plays a significant role in ensuring durability and weather resistance for various construction and industrial applications. Galvalume, comprising 55% aluminum and 45% zinc, offers lightweight, energy-efficient properties, and superior corrosion resistance. On the other hand, Galvanized, with a 100% zinc coating, provides increased edge and scratch protection for the sheets. Both finishes excel in corrosion resistance, yet Galvalume outperforms Galvanized overall. The decision between Galvalume and Galvanized finishes depends on factors like cost, application requirements, and the desired level of protection needed for the corrugated steel sheets. Selecting the appropriate finish is vital for enhancing the longevity and performance of the corrugated steel sheets.

Applications of Corrugated Steel Sheet

Corrugated steel sheets find extensive use in a variety of construction projects and industrial applications due to their exceptional strength-to-weight ratio and superior durability. Commonly employed for roofing, siding, and paneling, corrugated steel sheets offer advanced protection qualities such as weather resistance and durability. These sheets are also utilized in decorative screens and fencing applications. The high strength-to-weight ratio of corrugated steel panels makes them suitable for various structural purposes, providing resistance to impact and heavy loads. Their grooves enhance tensile strength, making them a versatile option for different projects where durability and weather resistance are essential. Corrugated steel sheets are recognized for their easy maintenance and unmatched protective qualities in the construction industry.

Sustainable Aspects of Corrugated Steel Sheet

With a focus on sustainability, the recyclability and long lifespan of corrugated steel sheets make them an environmentally conscious choice for construction projects. Made from galvanized steel, typically in 31-gauge thickness, these sheets are commonly used for roofing due to their sustainable properties. Their lightweight nature not only reduces transportation energy and costs during installation but also contributes to overall energy savings. The durability of corrugated steel sheets is well-known, as they can withstand harsh weather conditions and provide long-term protection to structures. By choosing corrugated steel sheets, builders opt for a sustainable material that offers both strength and eco-friendliness, making them a preferred option for various construction applications.

Installation of Corrugated Steel Sheet

The proper fastening of corrugated steel sheets to the structure is essential for ensuring their secure installation and long-term performance. Corrugated steel sheets are typically installed using rust-resistant screws or nails to secure them to the framework, creating a watertight seal through proper overlapping. It is vital to follow manufacturer guidelines during installation to guarantee structural integrity and prevent issues such as water infiltration. Creating a sturdy framework to support the panels is an integral part of the installation process, ensuring the sheets are securely attached to the structure. Using the recommended screws or nails helps prevent corrosion and prolongs the lifespan of the corrugated steel sheets, maintaining their functionality over time.

Maintenance Tips for Corrugated Steel Sheet

To guarantee the longevity and peak performance of corrugated steel sheets, routine maintenance practices are essential for preserving their integrity and appearance. Regularly cleaning the galvanized steel corrugated sheet metal with a mild detergent and water helps remove dirt and grime. It is important to inspect the sheets for any signs of rust or corrosion and address them promptly to prevent further damage. Applying a protective coating or paint can enhance the durability and weather resistance of the corrugated steel, while checking and tightening loose fasteners ensures the panels remain securely in place. Trimming overhanging branches or debris that may fall on the sheets also helps prevent damage, contributing to effective maintenance and rust prevention.

Frequently Asked Questions

What's the Difference Between Corrugated Steel and Galvanized Steel?

Corrugated steel and galvanized steel differ in their composition and purpose. Corrugated steel is prized for its strength and flexibility, while galvanized steel boasts enhanced corrosion resistance. Both materials find widespread application in construction and industrial contexts.

What Is Corrugated Sheet in Steel?

A corrugated sheet in steel refers to a material that has been shaped with repeating folds or ridges to enhance strength and durability. This unique design improves the structural integrity of the steel, making it suitable for various applications.

Is Corrugated Steel Expensive?

When evaluating the cost of corrugated steel, factors such as gauge thickness, coating type, and panel size influence pricing. Although initial expenses may be higher, its long-term durability, weather resistance, and low maintenance make it a cost-effective option in the construction industry.

How Thick Is Corrugated Steel?

Corrugated steel thickness ranges typically from 26 to 29 gauge. Lower gauge numbers signify thicker sheets, providing enhanced strength and durability. The choice of thickness depends on project requirements and structural needs for best performance.