Expanded metal sheets are a lightweight yet durable option, offering an aesthetic appeal with intricate patterns suitable for decorative uses. Their versatility extends to fencing, material separation, and providing protection and ventilation for machinery guards. Customization options cater to specific project needs, enhancing design possibilities. Quality assurance is guaranteed by following industry standards, including cold rolled steel with magnetic properties for various applications. For successful installation, it is crucial to utilize appropriate tools, secure sheets properly, and apply protective coatings, ensuring long-lasting performance. Discover more about the benefits and applications of expanded metal sheets for your projects.

Key Takeaways

- Lightweight yet durable construction for various applications.

- Aesthetic appeal and modern touch in decorative uses.

- Versatile structural properties for fencing, barriers, and walkways.

- Customizable options for tailored solutions and design flexibility.

- Adherence to industry standards for quality assurance and performance.

Benefits of Expanded Metal Sheet

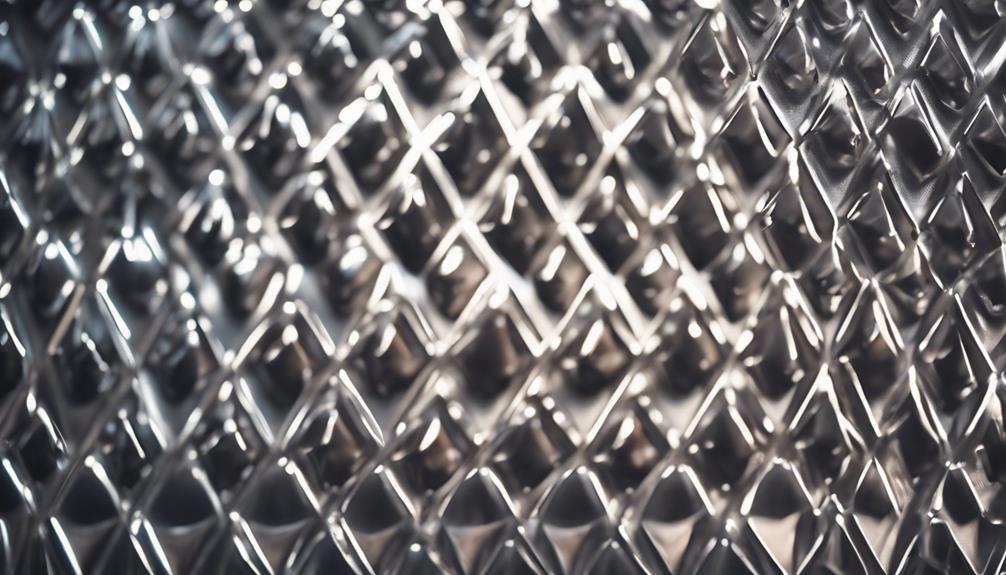

Featuring a lightweight yet durable construction, steel expanded metal sheets offer a multitude of benefits for various industrial and decorative applications. In the domain of decorative uses, steel expanded metal sheets provide not only functionality but also an aesthetic appeal. The intricate patterns created by the expanding process give these sheets a visually pleasing ornamental effect, making them popular choices for architectural and interior design projects. Whether used as room dividers, wall cladding, or furniture accents, steel expanded metal sheets add a modern and stylish touch to any space. Additionally, the versatility of these sheets allows for creative customization, enabling designers to achieve unique and eye-catching decorative elements in their projects.

Various Applications of Expanded Metal

Steel expanded metal sheets find diverse applications across various industries due to their versatility and unique structural properties. Commonly used in security applications, they are ideal for fencing and barriers. In sifting applications, these sheets excel at separating materials based on size. Machinery guards benefit from the incorporation of expanded metal sheets, providing both protection and ventilation. The durability of expanded metal sheets makes them a popular choice for industrial and commercial flooring. Additionally, walkways in outdoor areas utilize expanded metal sheets for their traction and drainage properties. These applications demonstrate the wide-ranging benefits of using steel expanded metal in various industrial and commercial settings.

Customization Options for Expanded Metal

Customization options for expanded metal sheets cater to specific project requirements, offering flexibility and tailored solutions for a variety of applications. These options include custom sizes, allowing expanded metal sheets to be tailored to fit precise project needs. Whether it's adjusting the dimensions or opting for custom cuts, the flexibility in customization guarantees that the expanded metal sheets can be perfectly aligned with the requirements of different applications. This tailored approach not only enhances the design possibilities but also contributes to the overall efficiency of the installation process. By offering custom sizes and cuts, metal fabricators can deliver personalized solutions that meet the unique demands of each project, making customized expanded metal sheets a versatile choice for various construction and design projects.

Quality Assurance for Expanded Metal Sheet

Ensuring the quality of expanded metal sheets is a critical aspect of meeting industry standards and guaranteeing the reliability of these versatile materials. Quality assurance for expanded metal sheets involves adherence to specifications such as MIL-M-17194D and ASTM F1267-91. Steel expanded metal sheets, often cold rolled, exhibit magnetic properties with a tensile strength of 52K+/- and yield strength of 38K+/-. These sheets, commonly used in various applications like security and flooring, offer weight and metal savings while permitting the free passage of light, liquid, sound, and air. The workability of expanded steel includes ease of welding, cutting, and forming with the appropriate equipment, making them a popular choice for different industrial needs.

Installation Tips for Expanded Metal

When installing expanded metal sheets, it is important to utilize appropriate tools for cutting and forming to achieve clean edges and precise shapes. Whether working with Galvanized Steel or Stainless Steel expanded metal, make sure the edges are smooth and free from burrs to prevent injuries during handling and installation. Secure the sheets in place using suitable fasteners such as screws, bolts, or clips to prevent any movement or displacement over time. Consider applying a protective coating or finish to enhance durability and corrosion resistance, especially in outdoor or high-moisture environments. Proper ventilation is essential when installing expanded metal in areas requiring airflow, like HVAC systems or machinery guards. Regular inspections and maintenance will help identify and address any damage promptly, ensuring long-lasting performance of the installed expanded metal sheets.

Frequently Asked Questions

What Sizes Do Expanded Metal Come In?

Expanded metal sheets come in various standard sizes such as 4 x 4 ft, 4 x 8 ft, and 5 x 10 ft. Custom cuts are also available to meet specific project requirements, allowing for flexibility and customization in applications.

What Does #9 Mean in Expanded Metal?

#9 in expanded metal denotes a specific thickness measurement. Understanding the gauge, like #9, is essential for selecting the appropriate expanded metal for various applications. It influences the strength, durability, rigidity, and flexibility of the sheet.

How Do You Expand Sheet Metal?

Expanding sheet metal involves a process of slitting and stretching a flat metal sheet to create diamond-shaped openings. This stretching enlarges the sheet while maintaining its strength. The versatility of expanded metal allows customization for specific project needs.

How Thick Is 16 Gauge Expanded Metal?

16 gauge expanded metal is approximately 0.0598 inches thick. This gauge strikes a balance between strength and flexibility, making it suitable for applications requiring durability and structural integrity. Understanding its thickness aids in selecting the right material for projects.