Corrugated sheets are highly durable and cost-effective construction materials used for a variety of purposes. Their versatility makes them a practical choice for siding, roofing, and packaging needs across different industries. The sheets offer exceptional weather resistance and protection, with customization options available for branding and design purposes. If you want to learn more about the various types, applications, and sustainability advantages of corrugated sheets, there is a wealth of information waiting to be explored.

Key Takeaways

- Exceptional durability and weather resistance for long-lasting use.

- Cost-effective solution with advanced protection for buildings.

- Versatile applications in construction projects.

- Sustainable, recyclable, and eco-friendly material.

- Customizable options available for branding and unique needs.

Benefits of Corrugated Sheet

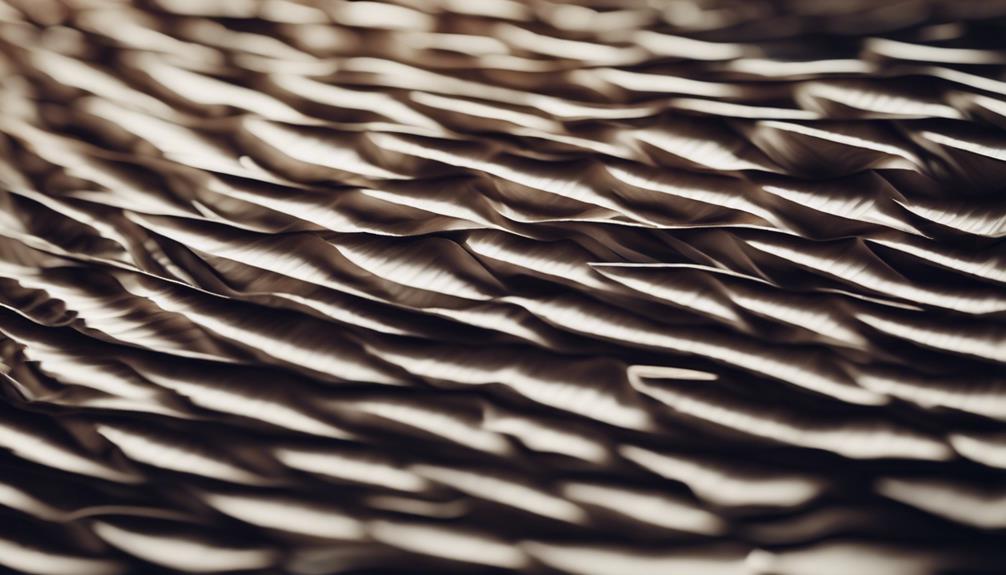

Corrugated sheet's exceptional durability and weather-resistant properties make it a highly sought-after material for various construction applications. Its ability to withstand harsh weather conditions while maintaining structural integrity sets it apart from other materials. Not only is it durable, but corrugated sheets are also cost-effective, offering long-term savings due to their low maintenance requirements and extended lifespan. The weather-resistant nature of these sheets guarantees that they remain in excellent condition even in challenging environments, providing advanced protection for buildings. This makes them a practical choice for siding, roofing, and paneling needs, where importance and longevity are essential factors. Galvalume and Galvanized options further enhance the durability and cost-effectiveness of corrugated sheets, making them a versatile solution for construction projects.

Types of Corrugated Sheet

Distinguished by their varying thicknesses and material compositions, the types of corrugated sheets available cater to a wide range of construction needs and preferences. Polycarbonate sheets offer a lightweight and durable option, ideal for applications requiring impact resistance and clarity. Galvanized/Galvalume corrugated metal sheets, with their zinc and aluminum finish, provide enhanced corrosion resistance, making them suitable for outdoor use. Thicknesses vary, ranging from 0.157 inches to 3/8 inches, allowing for flexibility in selecting the most appropriate sheet for specific projects. These corrugated sheets are commonly utilized for roofing, siding, paneling, decorative screens, and fencing due to their durability and weather-resistant properties. The various pattern types available, such as 1/2, 7/8, and AG, offer versatility and ease of installation.

Applications in Packaging Industry

Utilized extensively in the packaging industry, corrugated sheets play a crucial role in creating durable and protective solutions for shipping containers and boxes. Their strength and durability make them ideal for safeguarding products during transportation and storage. Corrugated sheets, available in various thicknesses and sizes, cater to different packaging needs. The design with fluted layers provides cushioning and impact resistance, preventing damage to packaged items. This material is preferred for its lightweight properties, cost-effectiveness, and recyclability in the packaging industry, making it a sustainable packaging choice. Overall, corrugated sheets are a versatile and reliable option for ensuring the safe delivery and storage of various goods.

Sustainability of Corrugated Sheet

A key aspect of the environmental impact of corrugated sheets lies in their sustainability as packaging materials derived from recycled paper or cardboard fibers. These sheets are recyclable, sustainable, and eco-friendly, making them an excellent choice for environmentally conscious packaging solutions. Due to their biodegradable nature, corrugated sheets help reduce environmental impact and promote eco-friendly practices. Additionally, they can be reused multiple times before recycling, proving to be a cost-effective and sustainable option for packaging needs. The production process of corrugated sheets also consumes less water and energy compared to other packaging materials, further enhancing their sustainability profile. By choosing corrugated sheets, businesses and consumers support a circular economy, utilizing renewable resources and minimizing waste generation.

Customization Options Available

When seeking packaging solutions, businesses and consumers can explore a range of customization options available to enhance branding and tailor packaging to specific needs. Custom printing services allow for logos and designs on packaging materials, while personalized ribbons and labels are offered for branding purposes. Custom-sized boxes and bags can be tailored to fit unique product dimensions, providing a perfect fit for the items being packaged. Additionally, customizable gift boxes are available for special events and occasions, adding a personal touch to gifts. These custom packaging solutions cater to businesses of all sizes, ensuring that diverse needs can be met effectively and efficiently.

Corrugated Sheet Vs. Other Materials

Comparing corrugated sheets to other materials reveals distinctive advantages regarding durability, versatility, and cost-efficiency. Corrugated sheets are preferred for roofing due to their high strength-to-weight ratio and resistance to elemental conditions like hail, snow, heat, wind, and fire. Compared to asphalt shingles and clay tiles, corrugated metal roofing is cost-effective, lightweight, durable, energy-efficient, long-lasting, and easy to install. Galvalume corrugated panels, made of 55% aluminum and 45% zinc, offer better overall corrosion resistance and energy efficiency compared to galvanized panels. Corrugated metal panels provide advanced protection qualities unmatched by other materials, making them a popular siding option for their durability and easy maintenance. Corrugated steel sheet products are tough, lightweight, and weather-resistant, suitable for various applications such as roofing, siding, paneling, decorative screens, and fencing.

Innovations in Corrugated Sheet Design

Innovations in corrugated sheet design have revolutionized the construction industry, offering enhanced durability and aesthetic versatility. Advanced materials such as Galvalume and Galvanized have been introduced to increase durability and weather resistance. New corrugated sheet patterns like 1/2, 7/8, and AG provide a range of aesthetic options for different applications. Additionally, the availability of corrugated metal panels in perforated aluminum expands the material choices for construction and design projects. Improved coatings like painted green, purlin, and weathering options not only offer enhanced protection but also provide a variety of style choices. With these advancements, companies like Industrial Metal Supply are able to offer a wide selection of corrugated sheet options to meet diverse project needs and design preferences.

Tips for Handling Corrugated Sheet

To guarantee proper handling of corrugated sheets, it is essential to adhere to recommended safety guidelines and best practices. When dealing with polycarbonate sheets of different thicknesses such as 1/4 in (6mm) and 0.3125 in (8mm), make sure to support them adequately to prevent breakage. Prices for these sheets can range from $7.98 to $186.00, making it vital to handle them with care to avoid unnecessary costs. Additionally, when working with corrugated plastic sheets available in white, black, and clear options, be mindful of their varying prices, which can range from $24.98 to $296.65 per package or case. By being cautious and following proper handling techniques, you can protect both yourself and the sheets from damage.

Cost-Effectiveness of Corrugated Sheet

Corrugated sheets stand out as a cost-effective packaging solution, offering businesses reliable and durable protection for their products during shipping and handling. These sheets provide cost-effective packaging options for businesses of all sizes, ensuring that fragile items are safeguarded during transit. Bulk pricing and discounts on large quantities make corrugated sheets an affordable choice, especially for companies looking to reduce packaging costs without compromising on quality. By utilizing corrugated sheets, businesses can rest assured that their products will reach customers in pristine condition, minimizing the risk of damage or breakage. The sturdy construction and reliable performance of corrugated sheets make them a cost-effective packaging option across various industries, proving their value in ensuring product safety and security.

Maintenance and Storage Guidelines

When maintaining and storing corrugated sheets, adherence to proper guidelines is important to preserve their integrity and longevity. Store prices may vary, so it's vital to protect your investment by following these best practices. Store the sheets vertically to prevent warping or bending, and avoid stacking heavy items on top to prevent damage. Regularly clean with mild soap and water to maintain their appearance, and inspect for wear or damage, repairing or replacing as needed. Consider applying UV protection coatings if the sheets will be exposed to sunlight to extend their lifespan. By following these guidelines, you can guarantee the corrugated sheets remain in excellent condition, protecting sensitive personal information and optimizing inventory levels.

Frequently Asked Questions

What Is a Corrugated Sheet?

A corrugated sheet is a versatile construction material used for siding, roofing, and other applications. It is known for its durability, lightweight composition, and resistance to various environmental factors, making it a popular choice in the construction industry.

What Is the Thickness of a Corrugated Sheet?

The thickness of a corrugated sheet can vary, ranging from 0.01 inches to 0.1 inches. Common options include 0.032 in, 0.039 in, 0.063 in, and 0.1 in. Selection depends on project requirements for durability and strength.

What Is Corrugated Plastic Sheet Called?

Corrugated plastic sheets are commonly referred to as Coroplast sheets. They are lightweight, durable, and made from polypropylene or polyethylene. These sheets have a twin-wall construction with fluted layers, providing added strength for various applications.

What's the Difference Between Corrugated Steel and Galvanized Steel?

Corrugated steel is characterized by its wavy shape providing strength, while galvanized steel is coated with zinc for corrosion resistance. The former offers structural support, the latter protects against rust. Their combination yields a durable, weather-resistant product.